PT. Ispat Panca Putera Product Specification

| These specifications are described for reinforcement steel as per SNI 07-2052-2014 and equivalent to JIS G 3112 | ||

| Plain Rounds (in mm) | : | 6,8,10,12,14,16,19,22,25,28 and 32 |

| Deformed Bars (in mm) | : | D6,D8,D10,D13,D14,D16,D19,D22,D25,D29 and D32 and D40 |

Mechanical Properties as per SNI 07-2052-2014

|

Steel Grade |

No. of Test Bars |

Tensile Test |

Bend Test |

Ratio Ts/Ys |

|||

|

Yield Kgf / mm2 (N/mm2) |

Tensile Kgf / mm2 (N/mm2) |

Elongation

(%) |

Rounded Corner |

Arch Diameter |

|||

|

BjTP 24 |

No. 2 |

Minimum 24 235 |

Minimum 39 380 |

20 |

1800 |

3 x d |

|

|

No. 3 |

24 |

||||||

|

BjTP 30 |

No. 2 |

Minimum 30 295 |

Minimum 45 440 |

18 |

1800 |

d > 16 = 3xd |

|

|

No. 3 |

20 |

d > 16 = 4xd |

|||||

|

BjTS 30 |

No. 2 |

Minimum 30 295 |

Minimum 45 440 |

10 |

1800 |

d ≤ 16 = 3xd |

|

|

No. 3 |

18 |

d > 16 = 4xd |

|||||

|

BjTS 35 |

No. 2 |

Minimum 35 345

|

Minimum 50 490

|

18 |

1800 |

d ≥ 16 = 3xd |

|

|

No. 3 |

20 |

16<d≤40 = 4xd d >= 40 = 5xd |

|||||

|

BjTS 40 |

No. 2 |

Minimum 40 390 |

Minimum 57 500 |

16 |

1800 |

5 x d |

Ratio = 1.2 min. |

|

No. 3 |

18 |

||||||

|

BjTS 50 |

No. 2 |

Minimum 50 490 |

Minimum 57 620 |

12 |

1800 |

d ≤ 25 = 5xd |

|

|

No. 3 |

14 |

d > 25 = 6xd |

|||||

Note :

- Bend test results should not be located on the outer side of the arch.

- 1 Kgf / mm2 = 9.8 N/mm2

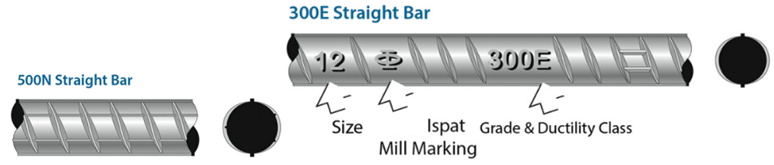

| These specifications are described for reinforcement steel as per AS/NZS 4671:2001 | ||

| Preferred diameter 500E | : | 6,10,12,16,20,25,32 and 40 ; Preferred diameter 300E : 6,10,12,16,20 and 25 |

| Preferred diameter 500N | : | 12,16,20,24,28,32 and 36 |

Mechanical properties ACRS as per AS/NZS 4671:2001

|

COMPOSITION OF REINFORCING STEELS |

|||||||||

|

Type of analysis |

Chemical composition, % max. |

Carbon equivalent value (Ceq) for standard grades |

|||||||

|

All grades |

|||||||||

|

C |

P |

S |

250N |

500L |

500N |

300E |

500E |

||

|

Cast analysis |

0.22 |

0.050 |

0.050 |

0.43 |

0.39 |

0.44 |

0.43 |

0.49 |

|

|

Product analysis |

0.24 |

0.055 |

0.055 |

0.45 |

0.41 |

0.46 |

0.45 |

0.51 |

|

|

CHARACTERISTIC MECHANICAL PROPERTIES OF REINFORCING STEELS |

||||||||

|

Property |

250N |

500L |

500N |

300E |

500E |

Type of specified value |

||

|

(Note 1) |

(Note 2) |

(Seismic) |

(Seismic) |

|||||

|

Yield stress (MPa) R ek.L R ek.U |

≥ 250 - |

≥ 500 ≤ 750 |

≥ 500 ≤ 650 |

≥ 300 ≤ 380 |

≥ 500 ≤ 600 |

CvL: p = 0.95 |

||

|

CvU: p = 0.05 |

||||||||

|

Ratio , Rm/Re

|

≥ 1.08 - |

≥ 1.03 - |

≥ 1.08 - |

≥ 1.15 ≥ 1.50 |

≥ 1.15 ≥ 1.4 0 |

CvL: p = 0.90 |

||

|

CvU: p = 0.10 |

||||||||

|

Uniform elongation A gt(%) |

≥ 5.0 |

≥ 1.5 |

≥ 5.0 |

≥ 15.0 |

≥ 10.0 |

CvL: p = 0.90 |

||

|

NOTES: : |

||||||||

|

These specifications are described for reinforcement steel as per SIRIM MS 146:2006

Preferred diameter all grade : 10,12,16,20,25,32 and 40

|

Grade |

Chemical Composition |

Size (mm) |

yield min. (N/mm2) |

Stress Ratio min. (Rm/Re) |

Elongation min. (%) |

|||||

|

C % max. |

Si % max. |

Mn % max. |

P % max. |

S % max. |

CE % max. |

|||||

|

High Yield Deformed Bar G460 |

0.25 |

- |

- |

0.05 |

0.05 |

0.51 |

All sizes |

460 |

1.05 |

12 |

|

High Yield Deformed Bar G500 |

0.3 |

- |

- |

0.05 |

0.05 |

0.51 |

All sizes |

500 |

1.05 |

12 |

|

Mild Steel Round Bar G250 |

0.25 |

- |

- |

0.06 |

0.06 |

0.42 |

All sizes |

250 |

1.05 |

22 |